TotalEnergies developed a predictive model based on historical and future data that allows the company to adjust its production according to projected gas demand. This solution is not only about optimization and the intelligent use of data but also about caring for the planet’s resources and ensuring their availability for the consumption and development of humankind. More than data, this is science with data.

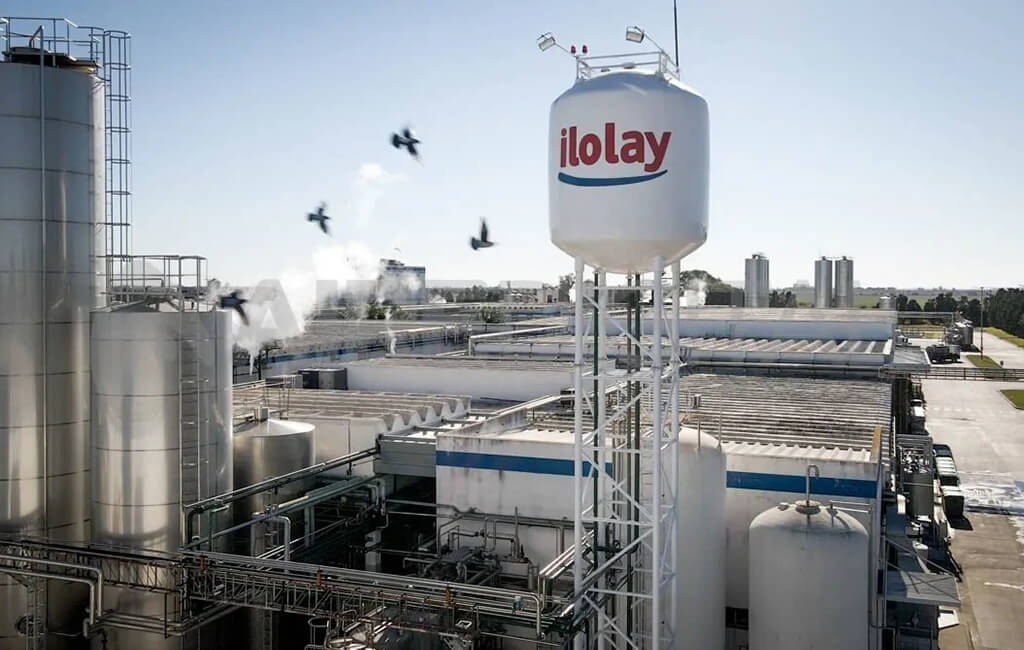

TotalEnergies is a multinational company active in more than 130 countries and it has over 100,000 employees worldwide.

Since the company started its operations in Argentina, in 1978, it has become a major player in oil and gas exploration and production as well as in gas transportation and petroleum product distribution. Today, its gas production represents 26% of the total gas extracted in Argentina.

TotalEnergies seeks to be a pioneer in optimizing production and drilling methods through innovation and R&D in robotics and digital technologies, so as to maximize the energy efficiency at its facilities and ensure that not a single drop of fuel is wasted.

The context

In May 2021, Total decided to join the energy transformation that some companies in the sector were beginning to carry out. The company changed its name to TotalEnergies and renewed its corporate image in line with its strategy to be a multi-energy company, which is related to caring for the environment and sustainable development.

“Energy is life. We all need it and it’s a source of progress. So today, to contribute to the sustainable development of the planet facing the climate challenge, we are moving forward, together, towards new energies,” declared Patrick Pouyanné, Chairman & CEO of TotalEnergies, after the Shareholders’ Meeting in which the changes were approved.

The challenge

In the oil and gas industry, it is vital to ensure a constant flow of petroleum products that supply industries, essential services and gas stations.

It is clear that market shortages are not an option, but neither is overproduction. The gas that cannot be sold has to be stored in extraction wells, which restricts the subsequent production. When doing business, time is money and profitability cannot be jeopardized by a mismatch between supply and demand.

To be able to set optimal production levels necessarily implies predicting several indicators, and it becomes a complex task because it requires analyzing a lot of information from different sources and in a range of formats. Previously, in TotalEnergies estimates were made manually, which demanded hours of work from specialists.

The company needed a solution that speeded up the evaluation of scenarios and brought greater certainty to conclusions. In order to do so, it was necessary to seek a consistent digital solution, driven by data, which will provide more information and insights for decision-making.

The solution

Transforming data into useful and reliable information, that’s what it was all about. From the beginning, TotalEnergies and Axonier worked together to understand how to connect the predictions of demand with the supply existing at any given moment, so as to provide support for future operating and business decisions that the company will need to make.

The solution was based on a predictive model of Machine Learning, applying Data Science tools to the business, with a practical and evolutionary vision.

The new digital tool consists in an innovative solution with regard to the prediction of future scenarios that uses a wide range of variables to optimize gas production planning. Moreover, we integrated all the information obtained into a management dashboard, which, without doubt, makes the planning process more agile, simple and efficient for all those involved.

The result

By forecasting and projecting gas demand, TotalEnergies can optimize production and ensure efficiency throughout the value chain. It also provides a better experience for employees, who can quickly develop multiple possible scenarios and analyze results based on several factors. While the certainty of the information used for decision-making increases, new opportunities arise to redirect efforts towards tasks that add greater value.

Thanks to this solution, TotalEnergies reduces prediction errors, minimizes losses of resources and significantly lowers the carbon footprint. This is another step forward in the company’s efforts to contribute to the sustainable development of the planet, in connection with technology efficiency and caring for the environment.